VITA AKZENT LC composite stains

VITA AKZENT LC composite stains: an implant-prosthetic work of art in the esthetic zone

Author: Jürgen Freitag, Master Dental Technician, Bad Homburg, Germany

Good things take time! This is especially true in implantology when the gums in the esthetic zone are to be surgically reconstructed and shaped first. Long-term temporary restorations are an important tool for such gradual changes in the gingival architecture, as their shape determines the subsequent pontic design. Since the red esthetic can take time in these types of cases, it is important to consider the patient's morphology in the esthetic zone, along with the natural basic tooth shade and the individual shade effects over the longer therapy period. This way patients can feel comfortable with the esthetically visible area over a longer period of treatment. Regardless, a long-term temporary restoration still has to be manufactured efficiently and economically. The temporary restoration is still only a temporary solution. The following implant case shows how the new composite stain system VITA AKZENT LC (VITA Zahnfabrik, Bad Säckingen, Germany) creates an individual esthetic for the patient with very little hassle, using a three-dimensional effect on a CAD/CAM-supported monochromatic long-term temporary restoration made of the composite material VITA CAD-Temp (VITA Zahnfabrik, Bad Säckingen, Germany).

The implantology challenge

A younger female patient presented in the dental practice with extensive periodontal bone damage in her anterior upper jaw. After the periodontal therapy was completed, it was apparent that her two middle upper incisors were no longer able to be preserved. After extraction and healing, an implant was placed in region 11 and 21 in combination with a bone augmentation. However, the bone did not remain stable, even after two additional augmentations. The decision was made to compensate for the esthetic deficits with a gingivoplasty after the long-term temporary restoration. A fixation impression of the clinical situation and the determination of the tooth shade with VITA classical A1-D4 served as the basis for the dental work (VITA Zahnfabrik, Bad Säckingen, Germany).

Implant-prosthetic long-term temporary

The corresponding titanium base was screwed into the manufactured and articulated master model with implant analogs and gingival mask, and the patient-specific abutment with optimized emergence profile was waxed up on it analogously. The screw channel was defined with a tubular modeling aid. The material selected for the implementation was sterilizable PEEK, since the material is chemically inert and biocompatible. The bone-like flexural modulus also ensures a 2/6 buffering function on the implant, which is rigidly anchored in the bone. The white shade of the material guarantees a deep-rooted esthetic. This was followed by the pinning of the wax model on the titanium base, embedding, burning out and the gap-free pressing of the titanium base with PEEK (BioHPP, Bredent, Senden, Germany). The finished and polished PEEK abutment was screwed onto the master model and the situation was scanned (3Shape D710, 3Shape, Copenhagen, Denmark). The temporary restoration was then splinted on 11 and 21 using the VITA CAD-Temp 3M2 monoColor composite designed in the CAD software, and then fabricated with CAD/CAM support (Zenotec mini, Wieland Dental, Pforzheim, Germany).

Two long-term temporary works of art

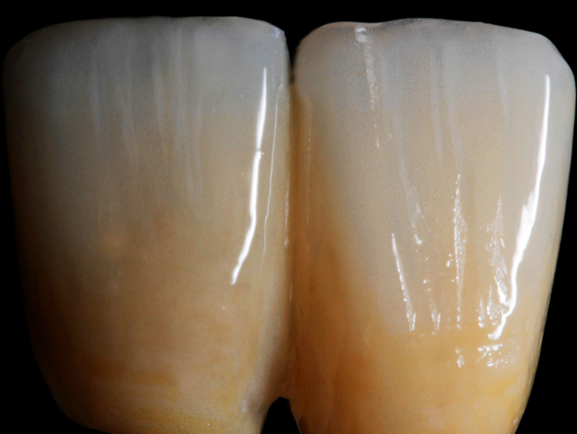

After finishing and polishing the long-term provisional composite crowns, the playful and multifaceted shade effect of the remaining natural teeth could be implemented chairside in direct comparison with the natural hard tooth substance. Intermediate curing was performed with the curing light. Translucency was simulated in the incisal area and on the flanks with VITA AKZENT LC EFFECT STAINS blue, grey and a touch of purple. Tiny indentations were made for enamel cracks and simply filled with russet or white. This was easy to do with the thin-bodied composite stains. Fluorosis was reproduced with white. Orange and khaki gave the dentine core a lively shimmer. A hint of khaki was also used circularly in the cervical area. The final light curing took place in the light oven for 90 seconds. A further 90 seconds of final curing was necessary after the full-coverage application of VITA AKZENT LC GLAZE in order to establish a homogeneous gloss level.

Conclusion: new shade flexibility

The consistency of the VITA AKZENT LC composite stains made targeted and selective application possible. After the final curing, no smearing was detectable on the restoration surfaces. In general, care should be taken when using the shades, as they are very intense. Conversely, the depletion of the stains is low, since the desired result is achieved with just a few brush strokes. VITA AKZENT LC is suitable for all polymers, composites and hybrid materials. In total prosthetics, the gingival anatomy can be reproduced on lip shields. Monolithic restorations made of composite and hybrid ceramic can be characterized efficiently and individually for the patient.

Thanks to their intensity, the stains are the material of choice for telescopic crowns in particular. Since primary and secondary crowns are used for this type of restoration, there is already very 3/6 little space for the composite veneer. Here, VITA AKZENT LC can be used as an internal stain and covered with a thin layer of enamel composite in order to shield it from natural abrasion over the long-term clinical course. This creates individual color effects and a natural translucency effect on the dentin core without wasting space. The maximum can be achieved with thin layers.

With the VITA AKZENT LC CHROMA STAINS, comprehensive adjustments to the basic tooth shade are also possible within a shade group in the VITA classical A1-D4 and in the VITA SYSTEM 3D-MASTER.

Absolutely natural result

In this case, the treating implantologist was absolutely thrilled with the result, which he noted could compete with a final restoration, in terms of esthetics. The patient was also happy about the integration, since the success and the end of the long treatment process became tangible for her for the first time. Thanks to efficient characterization with the composite stains VITA AKZENT LC, the longer therapeutic transition phase could be completed without esthetic deficits in the dental area.

Fig. 1: The white PEEK abutments were screwed onto the master model. 4/6

Fig. 2: The master model immediately before digitalization in the laboratory scanner.

Fig. 3: The integrated long-term temporary restoration made of the composite material VITA CAD-Temp monoColor.

Fig. 4: The long-term temporary restoration after characterization with the composite stains VITA AKZENT LC. 5/6

Fig. 5: The screwed-on abutments made of PEEK in the patient's mouth.

Fig. 6: The play of shade and light of the neighboring teeth has been naturally reproduced.

Fig. 7: Practioner and patient were absolutely delighted with the long-term temporary restoration. 6/6

VITA® and the names of the VITA products mentioned are registered trademarks of VITA Zahnfabrik H. Rauter GmbH & Co. KG, Bad Säckingen, Germany.