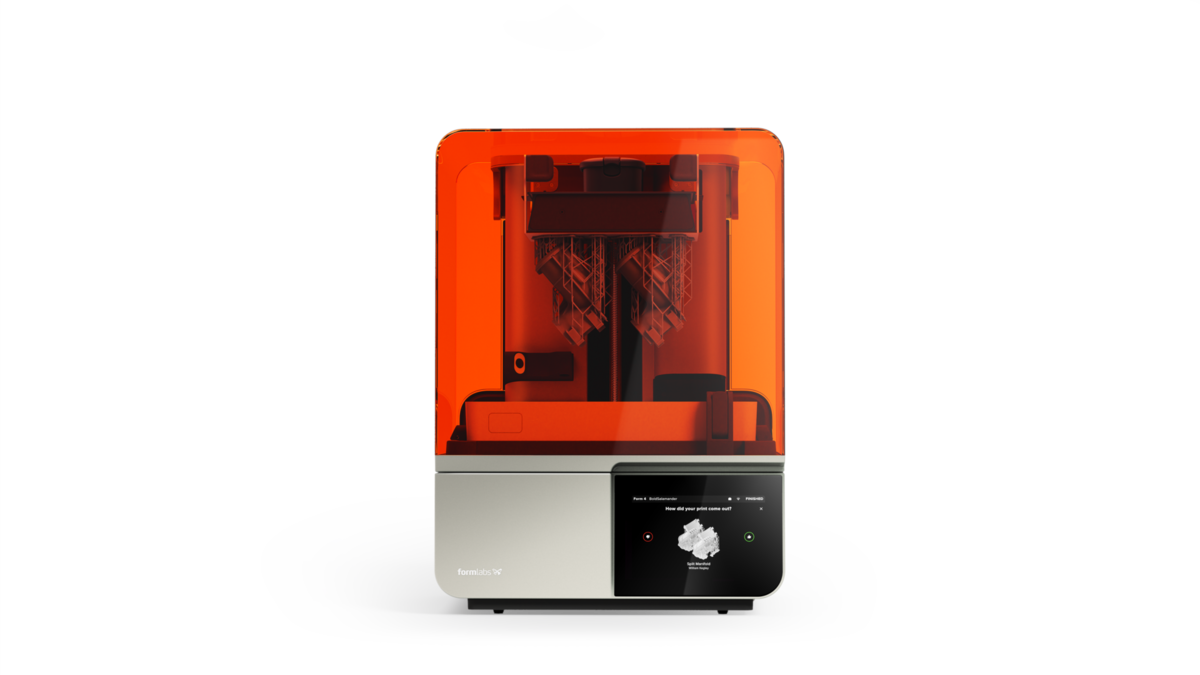

Introducing Formlabs' new 3D printer - Form 4B!

THE LATEST 3D PRINTER FROM FORMLABS

The next generation resin 3D printer that redefines the industry standard for speed, accuracy, reliability, and material versatility.

| Fast | Intuitive |

| 11 models in 9 minutes |

Anyone can learn in 15 minutes |

| Versatile | Accurate |

| 15+ Formlabs and thirdparty resins |

A perfect fit every time |

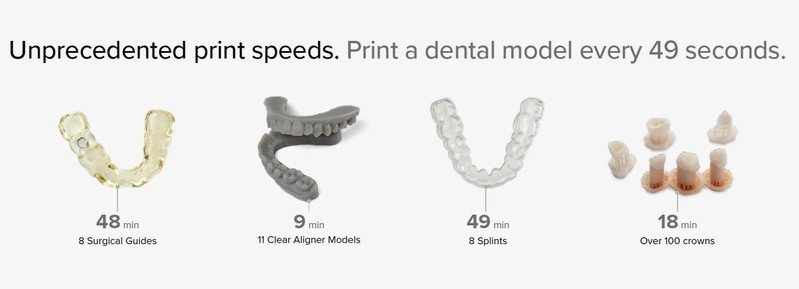

Form Series printers are being used for a wide range of dental indications including clear aligner models, surgical guides, permanent restorations, full dentures, temporary All-on-X appliances,...

Form 4B combines a new print engine with updates to the Formlabs Dental materials library of 15+ unique resins for dental applications, as well as new accessories and post-processing solutions, and an improved user experience. These updates reaffirm Formlabs’ dedication to the motto “Dentistry Made Easier.”

The Next Step in Dental 3D Printing

Form 4B with it's print speeds of up to 100 mm per hour creates opportunities for dentists, orthodontists, and labs, accelerating print speed, increasing build volume, expanding the material availability, and enabling accuracy anywhere on the build platform — all with effortless workflows that save time.

Speed is the primary pain point of dental professionals working on tight timelines. Form 4B is faster than ever, with the ability to print a model every minute — without compromising on accuracy. Print jobs are completed up to four times faster than with any other Form Series printer, regardless of whether you’re printing one part or a full build platform.

Low Force Display™ technology

Form 4B’s speed is driven by Formlabs’ new Low Force Display™ (LFD) Print Engine, a powerful combination of ultra-high power LEDs, collimating lenses, optical filters, and a robust liquid crystal display, that cures each layer of resin instantly — regardless of part size or quantity.

Ease of Use, Step By Step

The full Formlabs Dental ecosystem is designed to maximize efficiency and reduce the potential for print errors. Formlabs free print preparation software, PreForm Dental, automatically analyzes the part and determines the optimal orientation and support placement.

|

|

|

Print parts directly on the Build Platform Flex without supports. The Quick Release Technology of the Build Platform Flex enables the removal of parts in seconds. |

Parts are then automatically washed in the new Form Wash, with improved isopropyl alcohol agitation for a faster, cleaner process. The new Form Wash can adapt to fit build platforms from any Formlabs desktop printer. |