CC lite & CC Cool

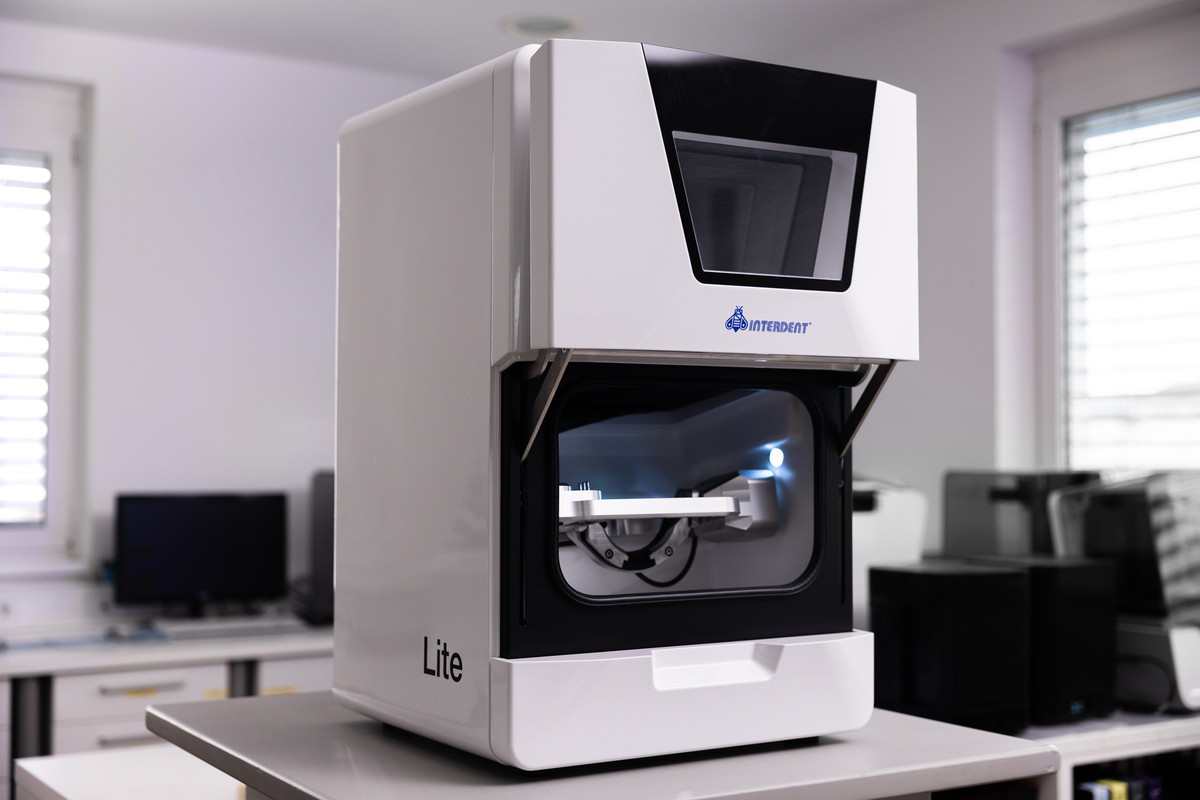

CC LITE

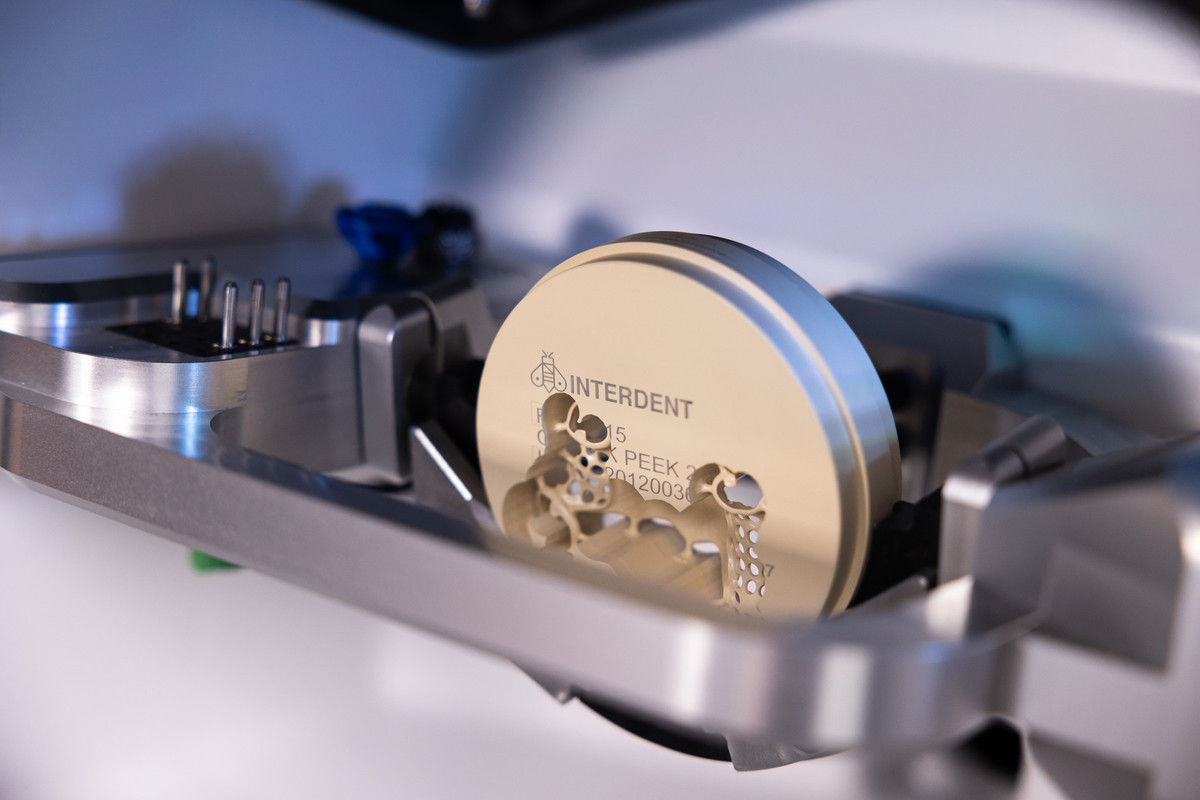

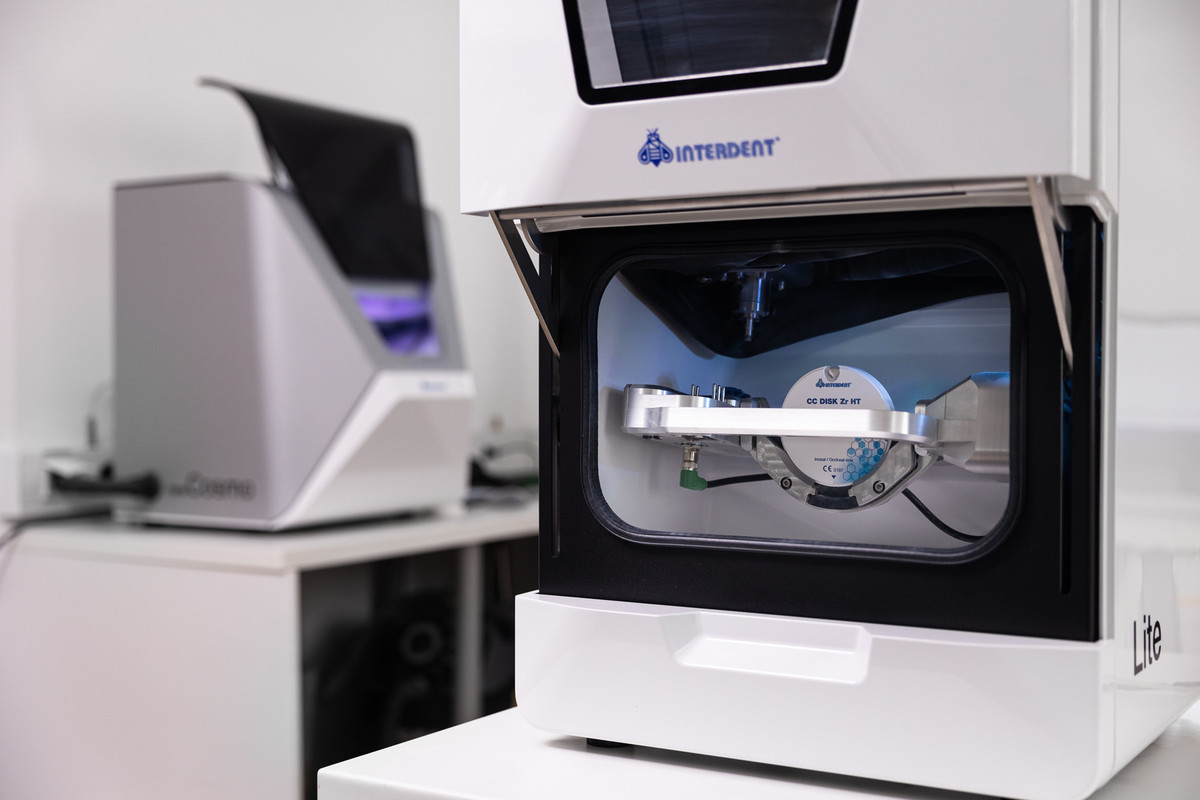

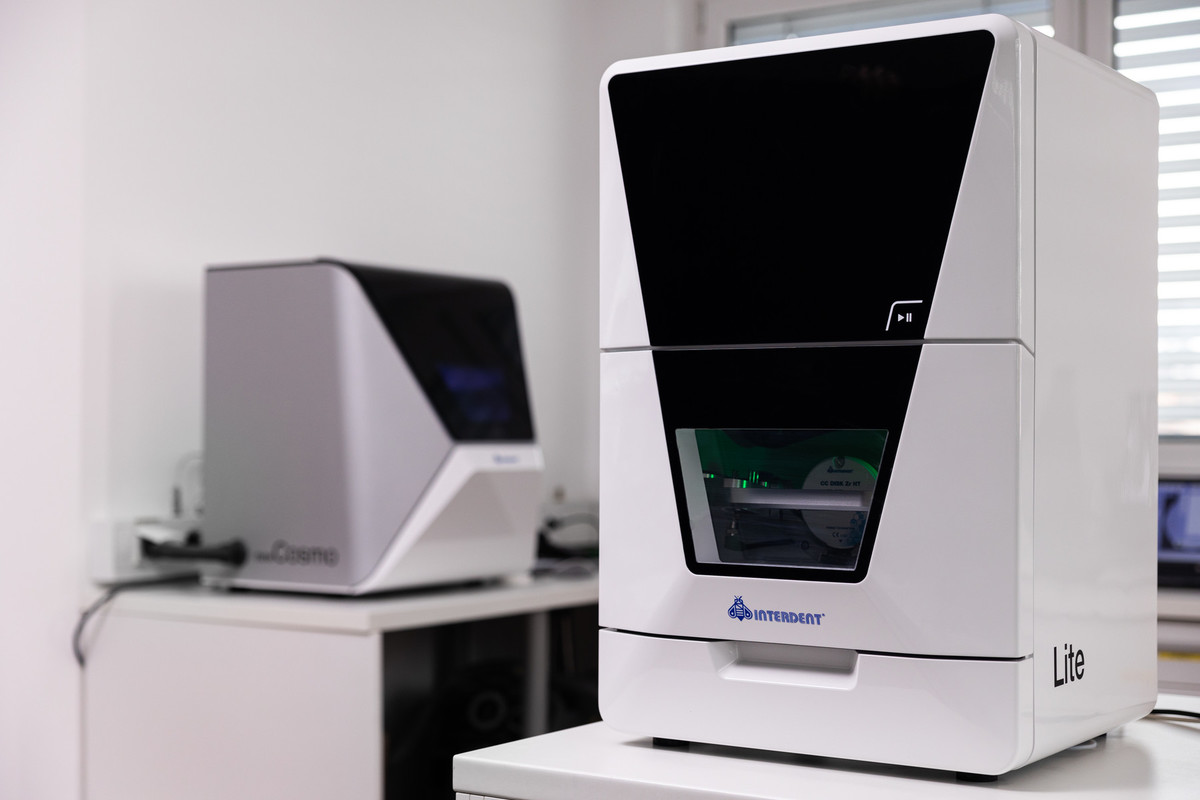

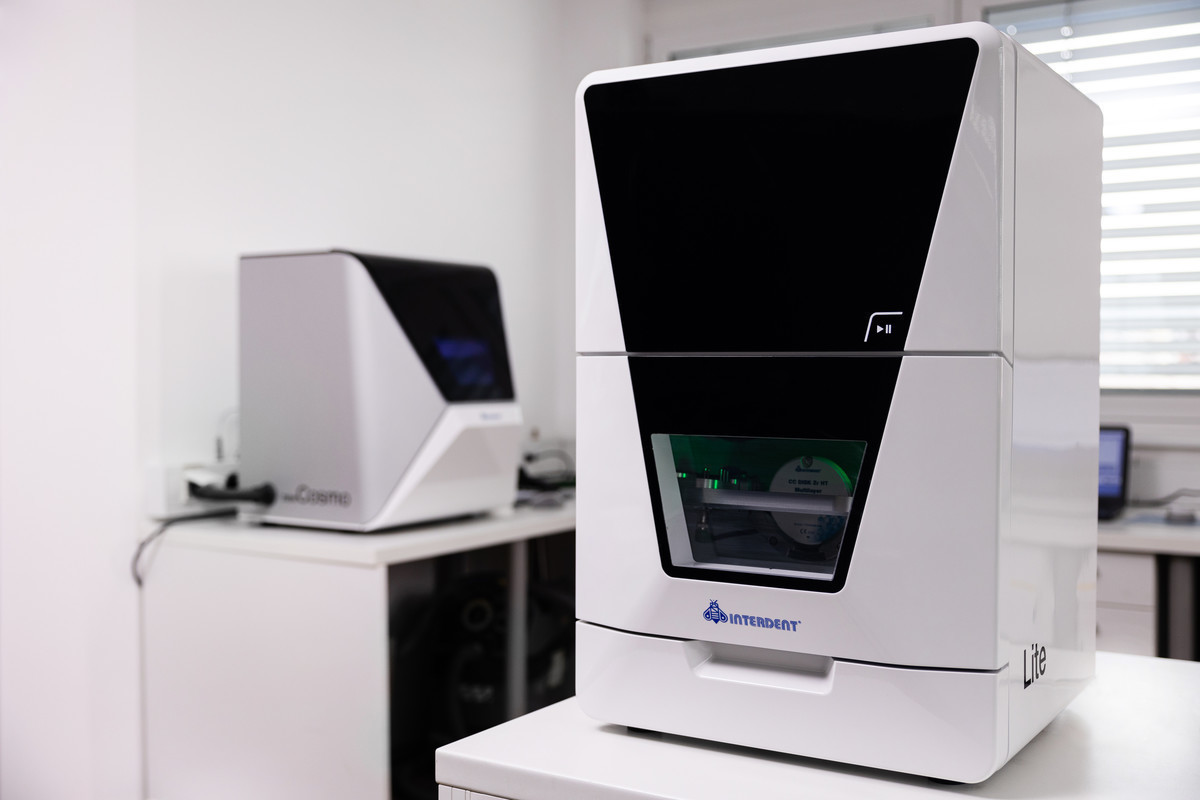

5-axis milling unit for dry milling with simple operation without the use of compressed air. It is suitable for discs or blocks of almost all materials from composites and zirconia to CoCr sintered metals.

CC Lite milling unit is due to the innovative and simple operation suitable for dental laboratories and practice labs.

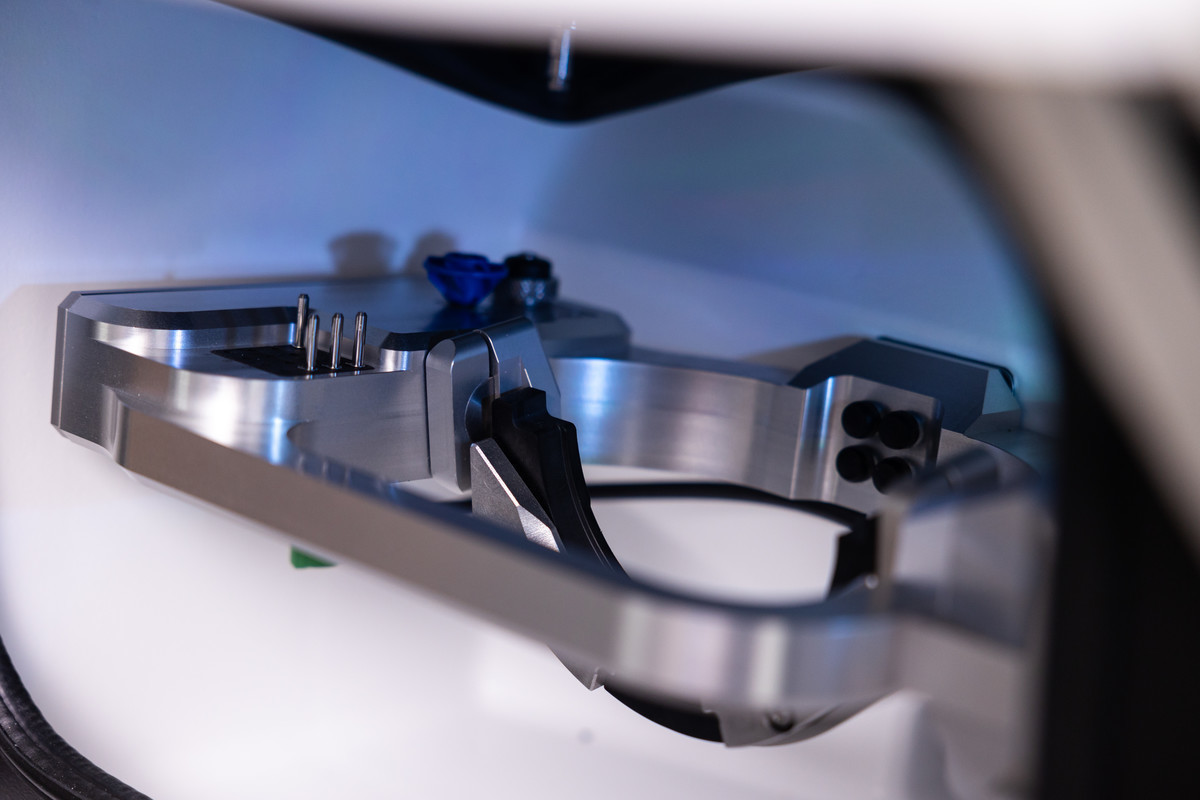

- Main motor: High-frequency spindle with electromechanical tool change (Germany)

- Motor speed: 60.000 rpm

- Engine power: 800 W

The CC Lite has a holder for up to 17 tools - 16 standard tools and an AIRTOOL. Thickness 10 – 40 mm, additional holder for blocks also available. Operation without the use of compressed air with the innovative AIRTOOL. Simple operation with the integrated Interdent dental CAM software featuring DIRECTMILL technology – no license fees payable.

|

|

|

|

|

Advantages:

- Mills almost all materials up to CoCr sintered metals in a 98.5 mm disc format, holders available for 110 mm discs and blocks.

- Integrated CAM software for immediate workflow (unpack, connect and start milling!) with maximum freedom in the choice of materials and scanners.

- No compressed air needed due to innovation of the CC Lite - AIRTOOL.

- The AIRTOOL (patent pending) uses its turbine blades to generate an air flow with no compressor or compressed air connection, which reliably keeps the workpiece free of dust and chippings. They are removed by vacuum from a dust collector.

- Automatic tool changer for 1 disc and for up to 6 blocks of different sizes.

- Benefits of optimum efficiency – maximum freedom of milling with minimal operating costs.

- Greatest indication diversity with a rotating angle of ± 35° in the 5th axis and discs up to 40 mm thick.

- 3 μm repetition accuracy.

- Easy service and ease of use.

- Lightweight machine and service-optimized design for easy transport, flexibility of use and environmentally friendly shipping.

- Cast aluminium body for low vibration in operation.

- Fast machining times and the best production results.

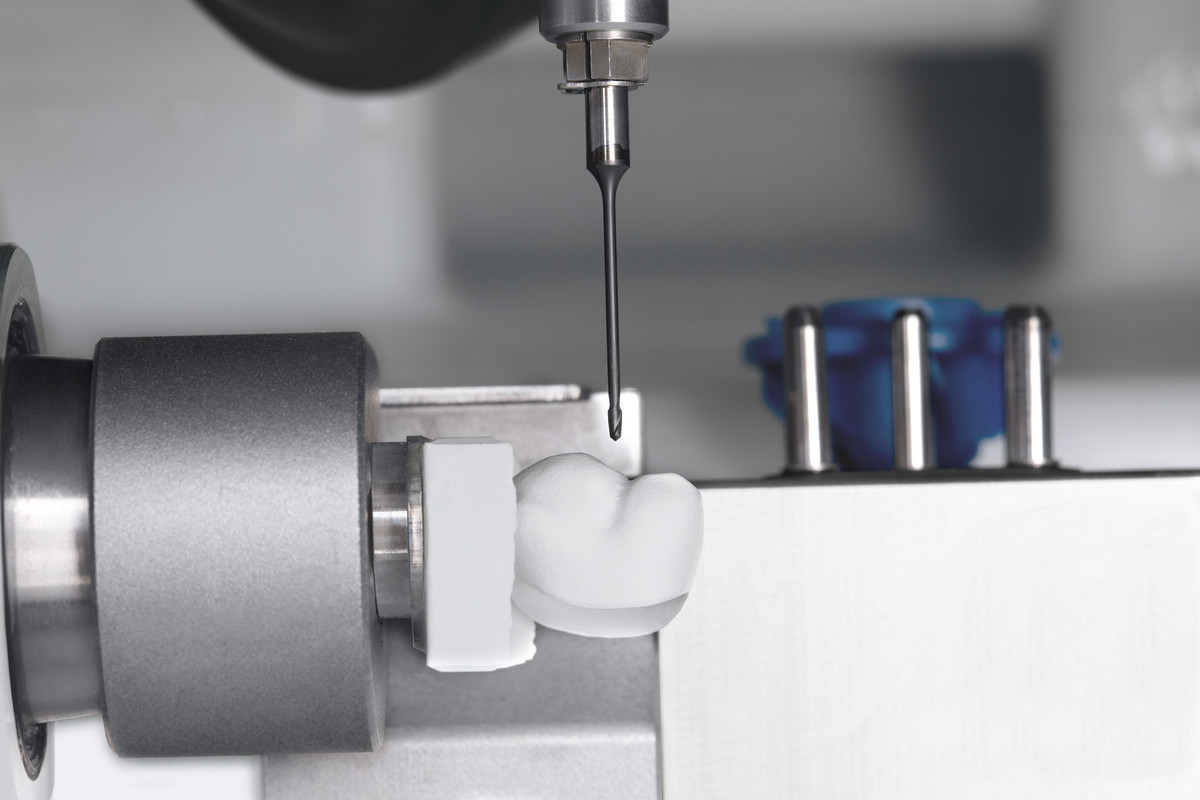

- Novelty: C-holder for 90° machining of anterior teeth.

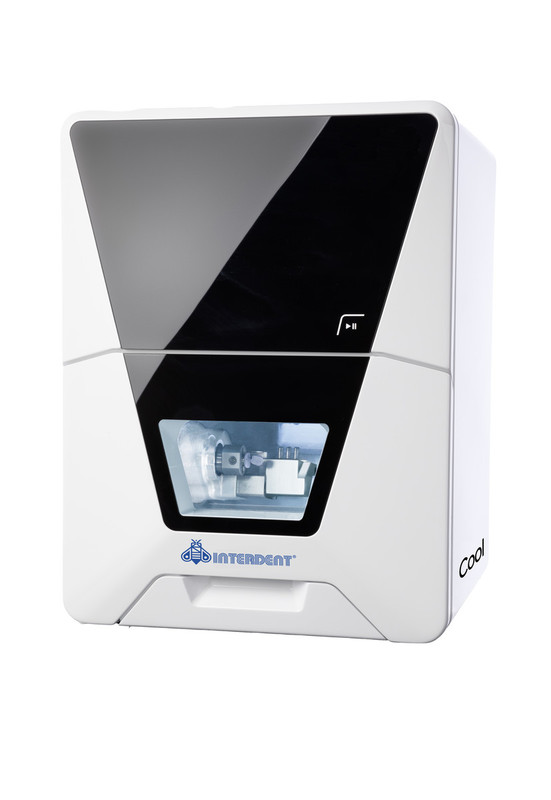

CC COOL

4-axis milling unit for wet and dry machining of blocks for chairside production and with CAM Software included.

CC Cool milling unit is due to the compact design, lightweight and no use of compressed air the best economical solution for dental practices. It processes materials from PMMA to glass ceramics.

- Main motor: High-frequency spindle with electromechanical tool change (Germany)

- Motor speed: 60.000 rpm

- Engine power: 800 W

The CC Cool has a holder for up to 6 tools and an AIRTOOL. Operation without the use of compressed air with the innovative AIRTOOL. Simple operation with the integrated Interdent dental CAM software featuring DIRECTMILL technology – no license fees payable.

Thanks to PUREWATER Technology, no grinding additives are required – which means trouble-free disposal and lower running costs.

|

|

|

|

|

Advantages:

- Mills almost all materials up to 45 mm in length including glass ceramics, composites, zirconium oxide and plastics in block format.

- Easy entry into in-house production.

- Integrated CAM software for immediate workflow (unpack, switch on and start milling) with maximum freedom in the choice of materials and suitable for all CAD software.

- Quick and easy switch between wet grinding and optional dry milling. Multi-compartment for cooling liquid tank or optional dry milling container.

- The PUREWATER Technology ensures that the closed liquid circuit in the machine requires no grinding additives. For you, this means easy disposal and even lower running costs.

- The optional dry container enables you to mill materials such as zirconia, PMMA and various composites with no cooling water or compressed air.

- No compressed air needed due to innovation of the CC Cool - AIRTOOL. The AIRTOOL (patent pending) uses its turbine blades to generate an air flow with no compressor or compressed air connection, which reliably keeps the workpiece free of dust and chippings. They are removed by vacuum from a dust collector.

- Quick restorations in just one session.

- 3 μm repetition accuracy.

- Machine design optimized for minimal weight and modular design for easy transport, flexibility of use and environmentally friendly shipping.